Packing the Pump Correctly:

![]() The importance of packing the pump correctly cannot

be overemphasized. Many packing failures are due to

the incorrect installation of the packing. The

following steps have been devised to ensure

effective installation of packings on pumps.

The importance of packing the pump correctly cannot

be overemphasized. Many packing failures are due to

the incorrect installation of the packing. The

following steps have been devised to ensure

effective installation of packings on pumps.

1. Remove all the old packing from the stuffing box.

![]() Clean box and shaft thoroughly and examine shaft

sleeve for wear and scoring. Replace shaft sleeve in

wear is excessive.

Clean box and shaft thoroughly and examine shaft

sleeve for wear and scoring. Replace shaft sleeve in

wear is excessive.

2. Choosing the correct cross-section of packing.

![]() To determine the correct ring size:

To determine the correct ring size:

A. Measure the diameter of the shaft (inside the

stuffing box area, if possible.)

B. Measure the diameter of the stuffing box (to give

the O.D. of the ring.)

C. Subtract the I.D. measurement from the O.D.,

measure and divide by two. The result is the

required cross section.

3. Cutting packing into rings.

![]() Figure 1: Hold the packing tightly on the mandrel,

but do not stretch excessively, and cut the ring(s).

Figure 1: Hold the packing tightly on the mandrel,

but do not stretch excessively, and cut the ring(s).

|

|

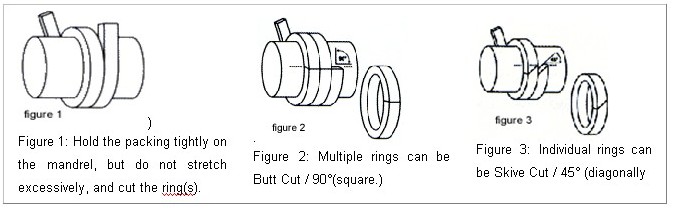

![]() The best way to cut packing rings is to cut them on

the mandrel with the same diameter as the shaft in

the stuffing box. If there is no wear, rings can be

cut on the shaft outside the stuffing box.Insert one ring at a time into the stuffing box,

making certain it fits the packing space properly.

Each additional ring can be cut in the same manner,

or the first ring can be used as a master from which

the balance of the rings are cut.If the Butt Cut

rings are cut on a flat surface, be certain that the

side of the master rings, and not the I.D. or O.D.

surface, is laid on the rings to be cut. This is

necessary so that the end rings can be

reproduced.When cutting Skive, diagonal joints, use

a maple miter board so that each successive ring can

be cut at the correct angle.

The best way to cut packing rings is to cut them on

the mandrel with the same diameter as the shaft in

the stuffing box. If there is no wear, rings can be

cut on the shaft outside the stuffing box.Insert one ring at a time into the stuffing box,

making certain it fits the packing space properly.

Each additional ring can be cut in the same manner,

or the first ring can be used as a master from which

the balance of the rings are cut.If the Butt Cut

rings are cut on a flat surface, be certain that the

side of the master rings, and not the I.D. or O.D.

surface, is laid on the rings to be cut. This is

necessary so that the end rings can be

reproduced.When cutting Skive, diagonal joints, use

a maple miter board so that each successive ring can

be cut at the correct angle.

It is necessary that rings be cut to the correct size. Otherwise, service life is reduced.

4. Install one ring at a time. Make sure the packing ring is clean and has not picked up any dirt in handling. If needed, lubricate the shaft and inside of the stuffing box.

Packing rings should be firmly seated in the stuffing box one at a time using a tamping tool...>>Next Page

|

|

[2] | NEXT |

|

Total 2 Page 1/2 |